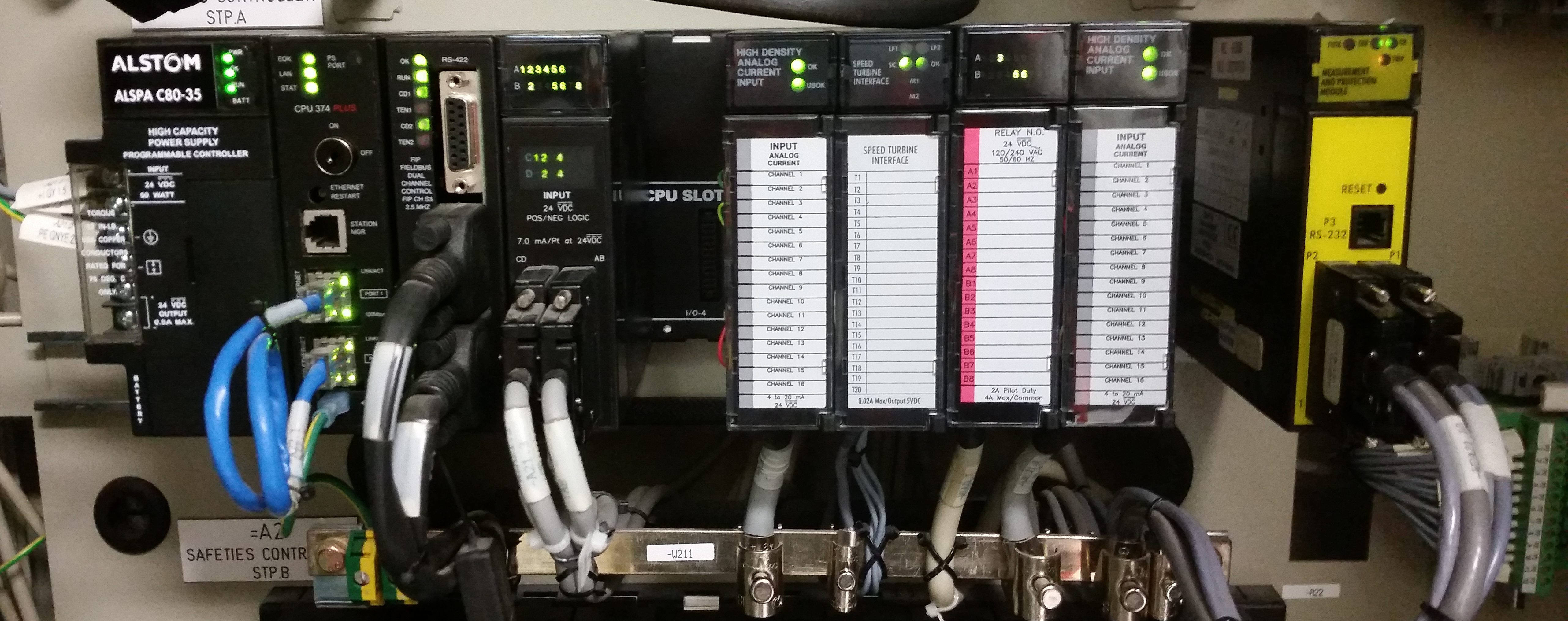

Alspa P320 TGC – Safety controller

Alspa P320 TGC – Safety controller

Distributed Control Systems (DCS) and automation are at the core of ICSS business.

Our experience in projects using Alstom products, such as Alspa P320 (all versions) allows us to cover any requirement of a project using this system, from training and basic modifications to expert’s tasks and customization of the system, including developing new functionalities never implemented on another project for specific requirements.

Regarding specifically Alspa P320, we can for instance perform tasks like:

- Performing the complete installation of the system.

- Perform any usual work: addition of a new PLC, of a new operator station, of a new program, of a new Controcad station, and so on.

- Replacing obsolete stations with virtual machines.

- Performing retrofits, migrations of projects.

- Implementing new functionalities (DEPP 2000, Historian, redundancy, alarm filtering, automated reports through IMS or CRW, and so on).

- Interfacing with a third-party system (deep knowledge and experience in communication protocols and their implementation in Alspa through CSS-G or CSS-F).

- Merging several projects (Controcad databases) in one.

- Developing new libraries, basic functions or functional blocks.

- Performing extremely deep tuning.

- Debugging the system and the logic.

- Performing any kind of training.

- Providing fully-independent expert-advice’s: obsolescence, required spare parts, advantage and risks of an upgrade, best way to implement a new regulation strategy, and so on.

However, ICSS is working on any kind of control systems (PCS7, PcVue, and so on).

For any control system, including of course Alspa P320, we can for instance:

- Design and implement changes in logic for any industrial process, with deep experience in Combined Cycle Power Plants.

- Implement and tune regulation loops.

- Perform any commissioning task.

- Provide expert-advice’s related to the process and risks associated with the control system.

- Solve instrumentation issues.

These lists are just examples, far from covering the full scope of tasks ICSS can perform on control systems, so don’t hesitate to contact us if you have a specific requirement.

*

* *

References:

-

Fujairah (Fujairah, UAE) – KA26 combined cycle (2 000 MW) with seawater desalination plant

DCS System engineer. Factory acceptance tests for the complete control system in Massy (France). Installation of the control system on site for the desalination plant. System commissioning. Troubleshooting of open items.

Alspa S6 DCS with TGC V2+ and Egatrol (interfaced through CSS-F GCOM).

-

Combigolfe (Fos-sur-Mer, France) – KA26 combined cycle (424 MW)

Installation of the control system on site and troubleshooting. Site acceptance tests. Troubleshooting of open items.

Alspa S6 DCS with Egatrol and Turbotrol (interfaced through CSS-F GCOM).

-

Le Havre unit 4 (Le Havre, France) – Coal (600 MW)

Several short interventions on site in order to troubleshoot and solve issues related to the upgrade of the control system.

Upgrade from P320 S4 with C370 and CE2000 PLCs (Controcad Unix) to Alspa P320 S6 through CSS-F gateways.

-

Intergen projects : Redbud, Magnolia, Seward (USA)

Retrofit of the steam turbine control system. Engineering, factory acceptance tests, and commissioning on site.

Keeping the old P320 TGC v1 controllers (C80-35 PLCs), upgrade of the Controcad projects from v3.2.5 to v4.5.1 and replacement of the Sun supervision stations from Centralog Unix to Alspa HMI based on Windows.

-

Kwinana (Perth, Western Australia) – KA13E2 combined cycle (320 MW)

Troubleshooting of open items at the end of the warranty period. Then, several site interventions and remote support to the customer.

P320 S5 DCS with TGC V2+, Egatrol and Siemens boiler management system for duct burners.

-

Aramon (Aramon, France) – Fuel (1 400 MW)

Expert assignment to troubleshoot and solve urgent issues blocking unit restart (complete loss of set points stations). Then, several site interventions and remote support to the customer.

P320 S5 DCS.

-

Provence unit 5 (Gardanne, France) – Coal (595 MW)

Mass modification of the logic of the control system. As the site wanted to change the behavior of all their valves, I wrote an SQL tool to change it automatically in the project without the need to change manually the logic. Implementation and testing on site.

P320 S5 DCS.

-

Belchatow (Belchatow, Poland) – Coal (5 420 MW)

System expert, supporting the installation of the DCS.

Alspa P320 S6 DCS.

-

Cycofos (Fos-sur-Mer, France) – KA26 combined cycle (400 MW)

Various interventions to support the customer.

P320 S5 DCS with Egatrol, now retrofitted to Alspa S6.

-

Terga (Aïn Temouchent, Algeria) – KA26 combined cycle (3×400 MW)

Installation and commissioning of the control system of the first unit.

Alspa S6 DCS, Trusted BPS, Egatrol and Turbotrol for machine control (interfaced through CSS-F 800xA).

-

DK6 (Dunkerque, France) – KA13E2 combined cycle (2×400 MW)

Installation of redundant channels on the boiler protection system and various interventions to support the customer.

P320 S5 Unix DCS, IEC104 CSS-G gateways, Matrikon OPC servers.

-

Ermenek (Göksu River, Turkey) – Hydraulic (2×150 MW)

Expert assignment to solve a blocking issue (impossibility to start the C80-35 PLCs on site, and to operate anything). Troubleshooting and correction on site.

P320 S5 Hydro.

-

GTX (Dubai, UAE) – GT13E2 (150 MW)

Installation of AGC control from dispatching center (IEC104).

P320 S5 DCS.

-

CCPP22 (Dubai, UAE) – KA13E2 combined cycle (430 MW)

Troubleshooting of several open items at the end of the warranty period. Installation of AGC control from the dispatching center (IEC104).

P320 S5 DCS.

-

Sulcis (Sardinia, Italia) – Coal (585 MW)

Emergency intervention on site – complete loss of supervision. Re-installation of the control system and root-cause analysis.

P320 S5 DCS.

-

Kureimat (El-Kureimat, Egypt) – Combined cycle (750 MW)

Several interventions to troubleshoot and close open items (cyber-security, communication protocols, network issues, logic issues, Historian issues…)

P320 S5 DCS.

-

Wimalasurendra (Nortonbridge, Sri Lanka) – Hydraulic (2×25 MW)

Installation and commissioning of the control system.

Alspa S6.1 Hydro : PLC CE1500 with EPL network and B&R stations.

-

Flevo (Flevo, Netherlands) – KA26 combined cycle (2×432 MW)

Several site interventions to troubleshoot and close open items.

Alspa S6 DCS with Egatrol.

-

Los Humeros (Puebla, Mexico) – Geothermal (2×25 MW)

Expert assignment to solve communication protocols issues (connection with the dispatching center).

Alspa S6 DCS.

-

Ghannouch (Gabes, Tunisia) – KA26 combined cycle (400 MW)

Troubleshooting of open items.

Alspa S6 DCS with Egatrol and Turbotrol.

-

Lucciana (Bastia, France) – Diesel (7×17 MW)

Instrumentation and commissioning, on-site studies for new systems to be implemented.

Siemens PCS7 DCS.

-

Tzafit (Kfar Menahem, Israel) – KA26 combined cycle (2×435 MW)

I&C commissioning engineer : HRSG ; WSC ; BOP ; system and interfaces issues. Startups, commissioning, operation, acceptance tests, logic changes.

Troubleshooting of interfacing issues.

Alspa S6 DCS, Controgas & Controsteam, Trusted (CE3500) BPS.

-

Niehl 3 (Cologne, Germany) – KA26 combined cycle (450 MW) with district heating

Commissioning engineer and interfaces specialist. Merging of the Controcad database of the 3 projects used for commissioning (Controgas, Controsteam, DCS) into a single project. Changes in various logic as well as in HRSG and WSC regulation.

Alspa S6 DCS, Controgas & Controsteam, Trusted (CE3500) BPS.